I had my first major problem with my extruder. I had been having strange flow problems. As I tried to diagnose this I noticed that I had some PLA leakage and then suddenly my nozzle was jamming into my build plate!! Upon closer examination the nozzle had slipped out about 0.25"!!!

The polyimide tape was wrapped right up to the insulator before.

This picture clearly shows the threads that are white (from the teflon tape) that have jumped out.

After taking it all apart there was a large blob of PLA stuck in the insulator.

I was never very happy with how close the nichrome had to be to the insulator and have read several articles about alternative methods of holding the heater to the nozzle. So I thought I would try an alternative with a T-nut and a brace. Here are some pictures of this experiment.

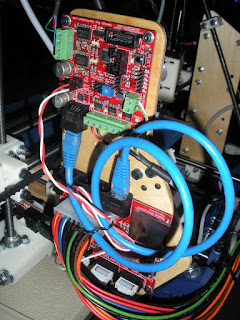

I needed some sort of plate at the extruder to hold the screws to the plate by the heater. So I made this adapter plate that also turned my extruder. Because my insulator/nozzle combination was already marginally long enough I made a short extension from wood.

I then bolted it all together and re-wrapped the heater and tried it out. I had concerns about the heat-sink that the aluminum plate created. These concerns I believe were warranted as the plate got quiet hot. I was able to get the nozzle hot enough to manually push the filament through but had trouble trying to push it through with the extruder.

I still am not happy with how short the heater section is and do not like how hot the plate and the screws up to the extruder get. So rather than continue to struggle with this design I bought a new nozzle set (from reifsnyderb) and am going back to a more traditional design for now.

For now I am out of commission but hope to have it all back together soon and start printing again.

Monday, June 28, 2010

Wednesday, June 23, 2010

Wednesday, June 16, 2010

Glowing PLA...

After receiving my PLA from UltiMachine on Monday I put the natural roll on and did some test prints. I was saving the blue translucent until after adjusting the machine a little more. For some reason I thought "I wonder if either of these PLAs glows under black-light?" So I dug out a black-light and tried, nothing from the natural but look what the blue does...

This is very cool and as far as I know previously undocumented. Here are some more pictures:

Also check out my video of this print on YouTube. And if you like fluorescent materials you should go buy some of this very cool PLA.

This is very cool and as far as I know previously undocumented. Here are some more pictures:

Also check out my video of this print on YouTube. And if you like fluorescent materials you should go buy some of this very cool PLA.

Monday, June 14, 2010

Plastic on my porch!!!

So far the materials I have used are some Makerbot ABS (Black and White), some UltiMachine PLA (Green), and some New Zealand (from Vik Olliver) PLA (red) from Metrix Create: Space. I prefer the PLA to the ABS as it warps less and smells much better. So I decided to order more PLA from UltiMachine. I ordered 5 lbs of Natural and 5 lbs of Blue Translucent. I also ordered some nichrome, polyimide tape, and a few thermistors. (for spare parts...)

Here is my un-boxing...

SURPRISE!!! they sent a sample piece (about 14 feet of each) of black and silver PLA...

They packaged the nichrome, polyimide tape, and thermistors very well in a inner envelope to protect them (complete with cardboard around the nichrome and thermistors). Overall I am very pleased so far. Now to start printing with my new plastic...

Here is my un-boxing...

SURPRISE!!! they sent a sample piece (about 14 feet of each) of black and silver PLA...

They packaged the nichrome, polyimide tape, and thermistors very well in a inner envelope to protect them (complete with cardboard around the nichrome and thermistors). Overall I am very pleased so far. Now to start printing with my new plastic...

Wednesday, June 9, 2010

Saturday, June 5, 2010

My Mendel Build (Main Frame)

Returning to some of the final build steps, I will now talk a little about the main frame.

For the frame rods I used all nylocks instead of the non-nylocks that the directions called for. The main challenge here was running them on, which was accomplished with the assistance of a power drill.

The rod was chucked up in the drill and the nut started on the end. Then with a box wrench on the nut the drill was spun to drive the nut on. The final adjustments were done by hand, but all the nuts were run close to there final places first.

The major change, besides the nylocks, was using Vik's "Footed Parametric Frame Vertex" The other change visible here is the modified z-axis lead screw bases I have already talked about.

Since I had changed some of the dimensions I determined the best way to locate the lead screw bases was by marking the center and lining that up with the center of the opening.

I then verified that both frames lined up and were flat.

I then assembled the cross bars. The one thing I would do more carefully next time would be to measure the locations of the nuts more carefully for the initial setting with the drill. I did not get them as close as I could have which made more work later.

Then I assembled the bulk of the frame.

Next came the X-axis assembly.

And the lead screws.

The lead screws, bearing rods and x-axis all must go in at the same time.

Next came the y-axis bearing rods.

I used a m4x20 bolt to help check for alignment.

Next I installed the optostops.

And finally the y-axis carriage.

The main change here was that I moved the belt splice to the bottom, for easier access. Also note the square rubber feet on the bottom of the frame vertex, and the diagonal pair of screws in the y-axis bearings instead of the four suggested.

Next time will be about Wade's extruder and the electronics.

For the frame rods I used all nylocks instead of the non-nylocks that the directions called for. The main challenge here was running them on, which was accomplished with the assistance of a power drill.

The rod was chucked up in the drill and the nut started on the end. Then with a box wrench on the nut the drill was spun to drive the nut on. The final adjustments were done by hand, but all the nuts were run close to there final places first.

The major change, besides the nylocks, was using Vik's "Footed Parametric Frame Vertex" The other change visible here is the modified z-axis lead screw bases I have already talked about.

Since I had changed some of the dimensions I determined the best way to locate the lead screw bases was by marking the center and lining that up with the center of the opening.

I then verified that both frames lined up and were flat.

I then assembled the cross bars. The one thing I would do more carefully next time would be to measure the locations of the nuts more carefully for the initial setting with the drill. I did not get them as close as I could have which made more work later.

Then I assembled the bulk of the frame.

Next came the X-axis assembly.

And the lead screws.

The lead screws, bearing rods and x-axis all must go in at the same time.

Next came the y-axis bearing rods.

I used a m4x20 bolt to help check for alignment.

Next I installed the optostops.

And finally the y-axis carriage.

The main change here was that I moved the belt splice to the bottom, for easier access. Also note the square rubber feet on the bottom of the frame vertex, and the diagonal pair of screws in the y-axis bearings instead of the four suggested.

Next time will be about Wade's extruder and the electronics.

Subscribe to:

Comments (Atom)